E2234 - August 24, 2022

Semiconductor Capital Equipment, the semi cycle, and geopolitical tensions

If you are new to Telltales, welcome! It’s great to have you here. This newsletter is designed to complement our weekly call/podcast and ultimately enable you develop your ability to think critically and independently about investments. Neither the podcast nor this newsletter provide ‘stock tips’ or financial advice. You should always do your own work to determine if an investment is suitable for you. If you are new, please check out the What is Telltales? post.

Every week I will provide additional data to supplement our weekly Telltales podcast. You can get the podcast on Apple Podcasts, Spotify, or SoundCloud.

Subscribe to this newsletter to stay up to date!

This week, in addition to energy and macro, we discussed semiconductor capital equipment and touched briefly on Lam Research. There is a lot to cover in order to fully understand the semiconductor manufacturing process. I wrote a couple overviews for our investors and followers back in 2020 that provide a decent overview that you may want to read up on if you are interested in the space.

If that is more than you want to read today, here’s a description from @_fabknowledge_ that I like…

…I think of building a semiconductor like laying a city filled with skyscrapers one floor at a time. Each step in the process either adds or subtracts a floor. After hundreds of steps, you then take a step back and you have your fully built “city”, complete with the hundreds of miniature skyscraper-like transistors.

Lam Research ($LRCX)

The following image, which I referenced in the memo on Semiconductor Fabrication (see above), provides a decent view of the semiconductor manufacturing process. It essentially involves a bunch of steps of adding and removing material in order to manufacture chips.

Lam Research specializes in Deposition, Etch, Strip & Clean, and Mass Metrology. You will notice that this is just part of the process, but has become increasingly specialized as the process nodes become smaller and more complex. Deposition processes create layers of dielectric (insulating) and metal (conducting) materials used to build a semiconductor device. Etch processes help create chip features by selectively removing films and materials that have been deposited on the wafer. Strip and clean techniques are used between manufacturing steps to eliminate unwanted material that could later lead to defects and to prepare the wafer surface for subsequent processing. Mass Metrology measures the change in mass following deposition, etch, and clean processes to enable monitoring and control of these often-repeated core manufacturing steps. This measurement enables atomic level quantification to process changes.

Next week we plan to talk a little more in depth on the financials. I recommend pulling the 10qs for both ASML and LRCX. However, the following tear sheet provides some comps in the SemiCap industry…

Further Reading

If this stuff is interesting to you, I can highly recommend the following two newsletters that provide deep insights into the industry that are often missed by analysts:

Supplemental Data

1 SuperCompounders

2 Macro

3 Energy

3.1 Oil & Gas

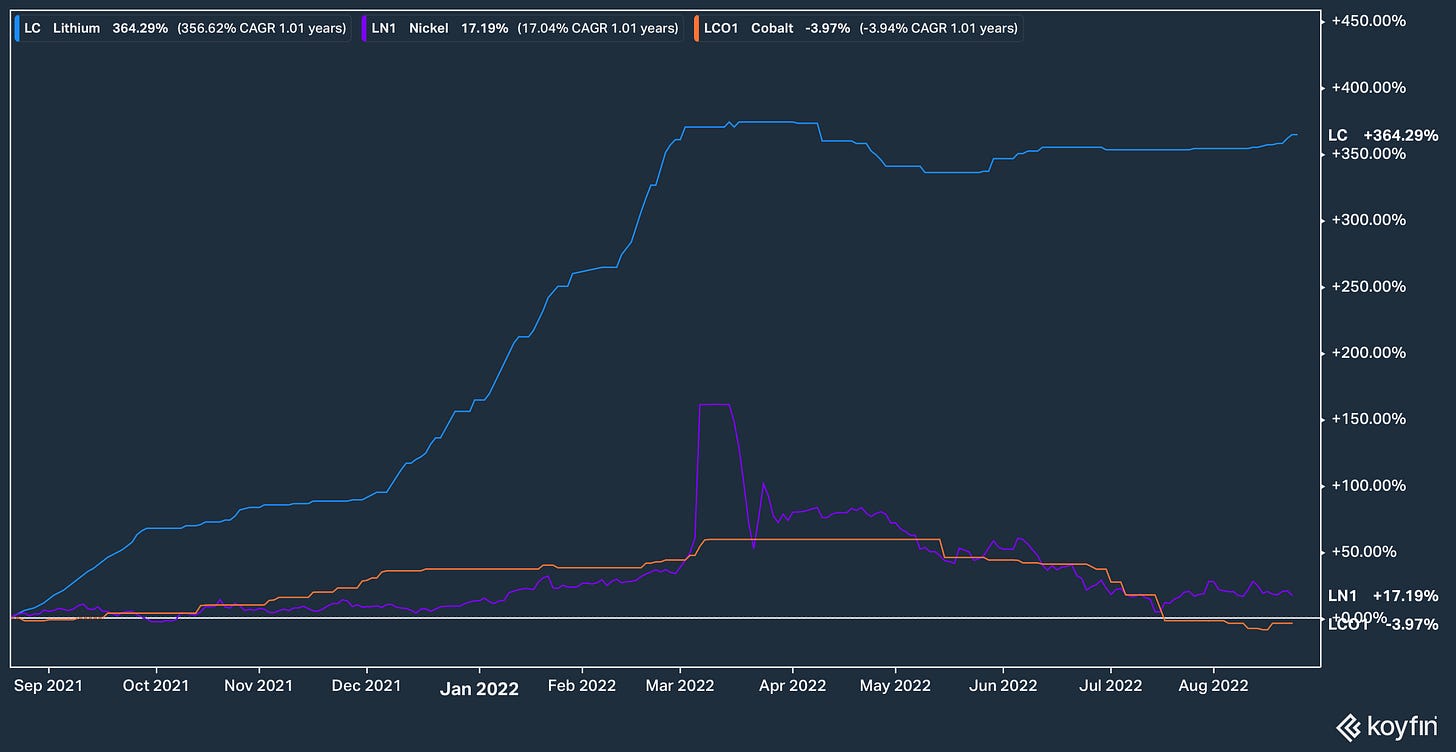

3.2 Metals Powered

4 Tech

Cloud Multiples - Check out the most recent edition of Clouded Judgement for the latest SaaS multiples.

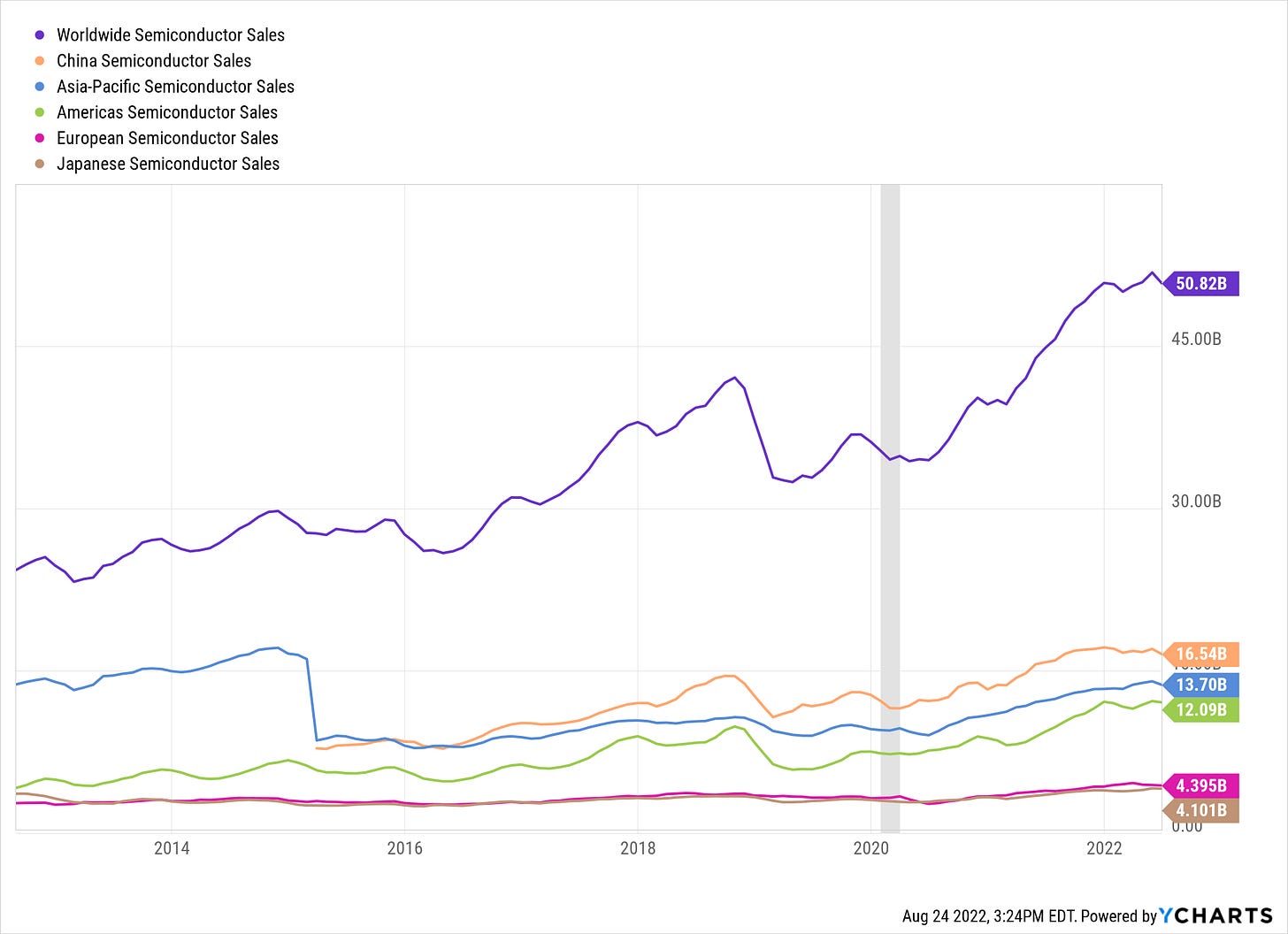

Semiconductors

Semiconductor Industry Association Global Billings Report

Bureau of Economic Analysis Semiconductor Import / Export

Cryptocurrency

Mentions: ASML 0.00%↑ LRCX 0.00%↑ AMAT 0.00%↑ $TOELY KLAC 0.00%↑ NVMI 0.00%↑ ONTO 0.00%↑

How did you like this week’s Telltales? Your feedback helps me make this great.

Loved | Great | Good | Meh | Bad | ….. If you liked this post from Telltales, why not share it?

This post and the information herein are intended for informational purposes only. The views expressed herein are the author’s alone and do not constitute an offer to sell, or a recommendation to purchase, or a solicitation of an offer to buy, any security, nor a recommendation for any investment product or service. While certain information contained herein has been obtained from sources believed to be reliable, neither the author nor any of his employers or their affiliates have independently verified this information, and its accuracy and completeness cannot be guaranteed. Accordingly, no representation or warranty, express or implied, is made as to, and no reliance should be placed on, the fairness, accuracy, timeliness or completeness of this information. The author and all employers and their affiliated persons assume no liability for this information and no obligation to update the information or analysis contained herein in the future.